Review: Dillon Precision’s 550B Progressive Reloading Press

Major Pandemic 05.18.16

During one of the serious ammo shortages, I broke my Lee Pro 1000 progressive press. While waiting for replacement parts, I bought a Dillon 550B. I have given that press quite a workout, loading thousands of rounds and many, many caliber swaps. It has been a reloading workhorse with zero downtime and I consider it a premium-quality reloading machine.

The reloading process is pretty simple and the same as any reloading press; knock out primer and resize brass, reprime, charge, flare case mouth for bullet seating, seat bullet, crimp, and on some rounds taper crimp. This process is simple when reloading one round at a time, but a progressive press handles more than one case at a time, so there is a lot to keep track of for the person running the press.

Add in automatic case feeding and indexing, and things can go wrong quickly if everything is not tuned perfectly. One little problem ends up being compounded as you realize that the last fifty rounds you reloaded did not have a primer due to primer feeding issues or that you’d run out of powder. You begin to scream words things like “drat” and “darn it all to heck” or perhaps some other four letter words…

The Dillon 550B is my third reloading press. I started with a single stage Lee Breech Lock Hand Press, and once I learned the basics, I graduated to a Lee Pro 1000 progressive loader designed for pistol calibers, which can in theory load up to 223 Remington case sizes. It was a decision based more on the $250 price than performance. I wanted to to load more ammo faster, so I thought I would jump into progressive reloading. The Lee Pro 1000 is not a bad or crappy reloader by any means, it is just not up to the volumes I produced. The end result was that I pushed it too hard and broke it. I needed something stronger that could take a beating.

Progressive Issues

I noticed that I lost a lot of control with auto-feeding progressive reloaders. Handgun cartridges were fairly problem-free during the reloading process once I had the Lee Loader tweaked and tuned. On the other hand, the longer 223 rifle cases were problematic on the Lee. A jammed round caused a linkage breakage, so I started looking for a different reloader to dedicate to calibers requiring more force, precision, and control during the reloading process.

The other issues with the Lee was that swapping calibers was a total pain in the butt. You could pop out the toolhead and leave the dies in place, but the shell plate and brass feeder were enormously painful to readjust, test, tweak, and re-adjust again to get working and feeding properly for each caliber. My decision was to just dedicate the Lee Pro1000 Loader for 9mm and go shopping for something to handle all the other calibers.

My FFL dealer swears by a used Dillon 550B he picked up in a gun trade. That used 550B takes a beating, loading thousands of rounds per month. The dealer told me it was one of the easiest loaders to swap calibers on, that it provided a high degree of precision, and struck a great balance between control and speed during the reloading process.

I flipped open my laptop and hit Dillon’s site to build a reloading kit to reload 357/38 Special, 223, and 308. I also ordered 9mm dies just in case my Lee press went offline again. The Dillon setup was not inexpensive–in fact, I have around $1100 invested in this setup if you count the press, dies, toolheads, and case gauges. It will easily cost me another $500 for all the other toolheads and dies I need for other calibers I would like to reload such as 10mm, 45 ACP, etc.

Despite the high cost, the Dillon 550B has been worth it and I have never regretted my decision to buy it. All my complaints about the Lee Pro 1000 were addressed on the 550B. High quality, rapid caliber swaps, high production volumes, and a ton of control during the reloading process. The Dillon 550B is an outstanding investment for any shooter.

About Dillon

Dillon has been around for a while making some of the most durable and reliable reloading equipment available. The company is probably most well-known for its booklet-sized quarterly catalog, which always features a beautiful fresh-faced lass tastefully posed on the front cover, usually with a gun. As a teenager, I loved to get my new Dillon catalog. Mrs. Pandemic refers to it as the “Girls Next Door With a Gun Catalog.” I guess that is where my girl-with-a-gun fantasy started and has never stopped.

Dillon Precision was actually the first company to offer an progressive press for the home reloader: the RL-1000. The company has done well for itself as a catalog driven manufacturing retailer, and today their products can also be found at sporting retailers around the globe.

Dillon has also been on the forefront of reloader technology and innovation. Dillon claims this 550B can produce 400+ rounds per hour, and their full-auto 650XL model is even faster and is noted to be one of the fastest home presses made. As a testament to the reliability of these presses, some people have added high torque motors and automation kits to the the 650XL to allow it to sit there and crank out rounds. In short, Dillon reloaders are known for tank-like durability and reliability. And if it ever does break, they have a lifetime warranty.

Fit, Finish, Feel and Features

While a Lee Pro 1000 costs around $250 with dies etc. for one cartridge, the Dillon Precision 550B runs around $750 for one cartridge. Additional dies and toolheads run about $100 per caliber. That noted, there is such a chasm of quality between the two products I would hardly call it a comparison.

I’m not saying that Lee is junk, it’s just a low-budget product. There is a pretty huge quality difference between the two loaders, although they look similar on paper to the beginner. The Dillon is significantly stronger, the quality is higher, and the tolerances tighter. The quality on the Dillon is every bit as nice as the RCBS, Redding, and Hornady loaders I have seen.

Where the Dillon excels over other brands is heavy duty durability, longevity, and consistent operation with parts built a bit heavier, thicker, or tougher than competing brands. All this durability provides a stiffer press, which leads to a more-precise, more-reliable round of ammo.

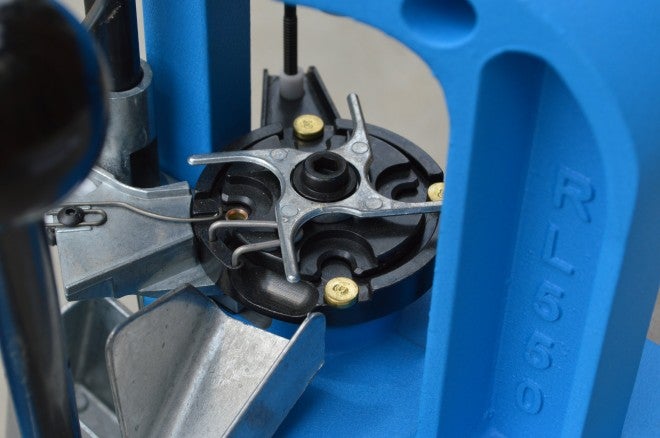

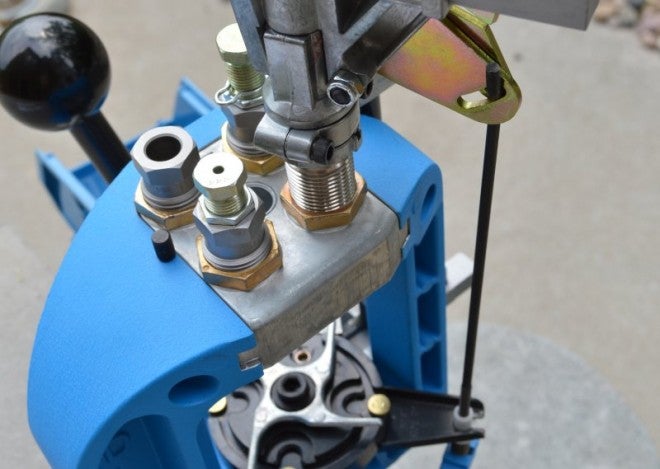

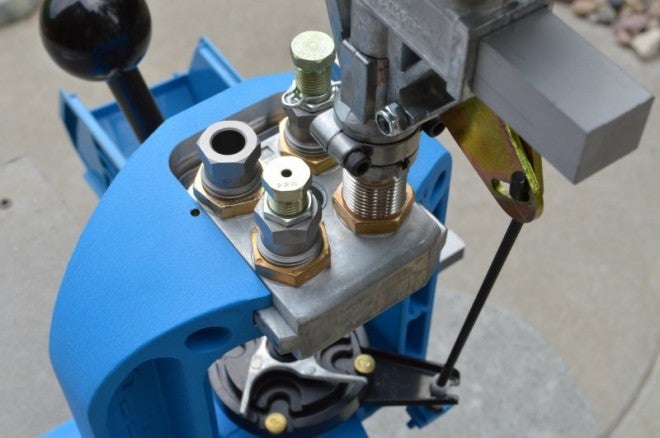

The Dillon 550B is a 4-position progressive reloader with Station 1 handling the resize, deprime, and prime functions, Station 2 dropping the powder and flaring the case, Station 4 reserved for bullet seating, and Station 4 performing case crimping. My Lee Pro1000 only had three stations, which meant I still needed to run rifle (or certain handgun calibers) back through for a final taper crimp, if desired.

The Dillon 550B’s four stations can handle it all in one pass. Every reloading manufacturer has their own version of how the reloading process should go, but many reloaders have noted that Dillon’s process increases reliability–and, according to some, safety. One benefit of Dillon’s staging sequence is that priming occurs at the first station, where an accidental primer ignition cannot ignite the powder reservoir. Great idea!

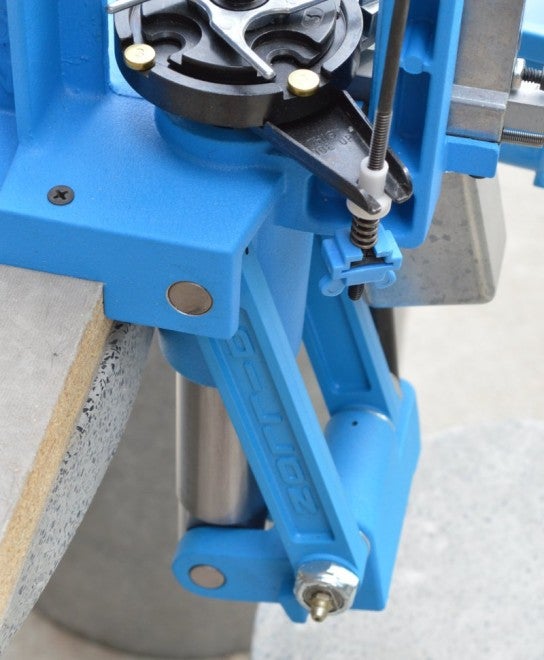

The 550B relies on your own hands to load the brass, add a bullet, and manually index the shell plate to the next station. This gives the user a best-of-both-worlds scenario, combining the control of a single stage press and the speed of a progressive press. Indexing and feeding by hand may sound tedious compared to automated progressive setups, but I like this level of control to assure that powder, bullet, seating, and crimping were all consistent.

With auto-indexing shell plates, if there is a problem, it can be difficult to remove the round or to work around the shell plate indexing mechanism. If you are just turning the shell plate by hand you have much more control. Hand-indexing the shell plate also has this enormous benefit: there are no wacky linkages or drive mechanisms to mess around with when you change shell plates. All you need to do on the Dillon 550B is just unbolt the shell plate and screw on a different one. That swap can be done in about a minute.

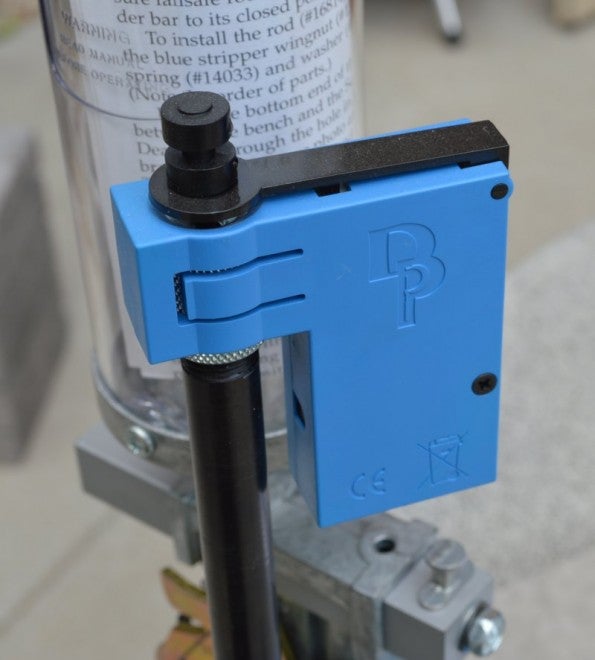

I found Dillon’s removable toolhead design to be a big time-saver for changing calibers. A removable toolhead allows your reloading dies to stay in the toolhead without affecting the adjustment. All that is required to change the toolhead for another cartridge is to lift the locking pin and slide out the toolhead.

When changing cartridges, you will of course want to make sure you change powders, and reset the powder measure to drop the appropriate powder charge for the cartridge you’re working with.

The beauty of the Dillon 550B design is that in less than 5 minutes, you can be swapped over to a new caliber just by swapping the shell plate, toolhead, potentially changing the contents of the primer tube, and emptying/refilling/resetting the powder measure. If you have a dedicated powder die or, better yet, a dedicated powder measure for each toolhead, then the conversion process is even faster. By contrast, my Lee Loader takes about 30 minutes including re-calibration and tuning.

Another big plus for me on the Dillon 550B was that it reloads nearly every handgun and rifle cartridge available without any modifications (other than an XL powder die for the really huge calibers). Buy a 550B once, and you can reload pretty much anything on it with the exception of 50 caliber. By my count, Dillon offers dies for more than 200 calibers for the 550B.

I do have a love/hate relationship with Dillon primer tubes. On one hand they are crazy reliable. On the other hand, the primer tubes are nowhere near as easy to reload as dumping a box of primers into my Lee primer tray and rattling them around until they are all upright. The Lee method is easy and fast but offers less-than-excellent reliability, while Dillon’s primer tube is slower to load but delivers good reliability. The primer tube does have a low primer warning, which I find convenient.

Final Thoughts

The Dillon 550B has been an awesome and reliable reloading machine for me. Do I still use my single stage press for reloading? Sure–and even my Lee Pro 1000 for 9mm–but the Dillon is a flexible press that minimizes cartridge change time and offers high rates of ammo production.

The beauty of the Dillon 550B is that once you get the toolhead set up, caliber swaps can take less than five minutes with a dedicated powder measure.

All in, all I am quite happy with the quality of the Dillon 550B and how flexible it has been reloading everything from 357 to 308. Buy the 550B once and you will never need to buy another press.

Specifications

- 4 station progressive loader

- Station 1) resize/deprime/prime

- Station 2) powder drop/flare

- Station 3) seat

- Station 4) crimp

- The RL550B is able to load rifle as well as pistol cartridges.

- The RL550B uses standard 7/8 by 14 thread per inch dies, as long as they deprime in the size die

- Manually indexed shellplate

- Manually fed cases and bullets Capable of loading 400 to 600 rounds per hour

- Lifetime “No-B.S.” Warranty

- No dies are included with the RL550B. If you need to order dies

The basic 550 includes:

- Machine with caliber conversion kit (shellplate, locator buttons, powder funnel) in the caliber of your choice.

- Powder measure with standard large and small powder bars (small installed), Small bar throws from 2.1 to 15 grains of powder Large bar throws up to 55 to 60 grains of powder.

- One prime system with large and small priming parts.

- One large and one small pick up tube

- Low Primer Alarm

- One toolhead

- One powder die

- One loaded cartridge catch bin

- One written instruction manual

- One set of standard Allen wrenches

- * No dies are included.

- Machine height from bench is 21″