AG Composites – The Gun Stock Company We Didn’t Know We Knew

Eve Flanigan 10.19.23

AG Composites is not exactly a household name, but any time spent shopping for a hunting rifle in the last 10 years has surely led most readers to see their products. The company makes carbon fiber stocks for a number of US rifle manufacturers. At the 2023 Outdoor News America Gun Writers’ Conference at Texas Gun Experience, writers including myself got a first-hand look at AG Composites’ wares as well as an orientation to the company’s manufacturing methods, history, and culture.

Firearm Stock Coverage on AllOutdoor

- Guide to PDW Stocks: The Good, Bad, and Ugly plus our 2023 Top Picks

- New SAUER 100 Rifles Featuring H-S Precision Stocks

- [SHOT 2023] DD Pro Chassis Folding Stock Adapter for Delta 5 Pro

- [SHOT 2023] DoubleStar CAR-15 Reproduction Stock

- AllOutdoor Review: From Boy to Man – Boyds Henry H001 Stock & Forend

Carbon fiber is a popular platform for bolt gun stocks for lots of good reasons. It’s lightweight, sturdy and impact-resistant, and very customizable in appearance. AG Composites grew from a simple idea when its founder and CEO, a former Army Ranger, noted its use in housing a spotting scope in the hunt field. Why not bring its weatherproof, shock-resistant qualities to rifle stocks? Through a long series of challenges, including a supplier who embezzled nearly all the fledgling company’s money and an industry that wasn’t ready for the concept of synthetic stocks, AG Composites eventually emerged as the world’s primary supplier of composite stocks. The company makes stocks for a number of household-name brands including Tikka, Springfield, Bergara, Kimber, Wilson Combat, Alamo Precision, and more. Nearly all are designed for the ubiquitous Remington 700 platform upon which most non-chassis hunting rifles are built. Individuals who want to “build” their own rifle can order direct from the company using their online rifle builder.

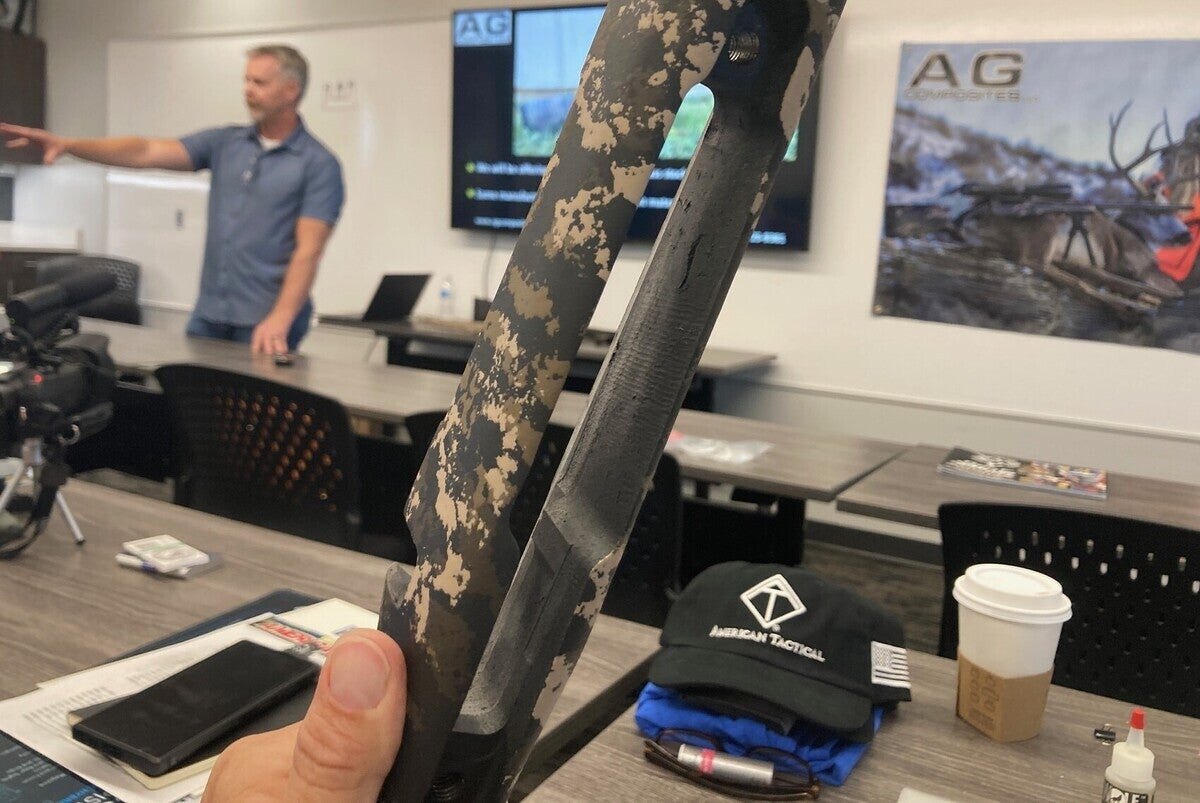

A surprising fact about the production of AG Composites’ stocks is how much the human touch is involved in production. There are 70 steps in the process, and 66 of them are done by human hands. Automation cuts the material, but hands perfect the shape and apply designs. Stocks are made in right/left halves, then melded together by a chemical process that yields one monolithic piece.

The Springfield Armory Waypoint rifle series is a good example of AG Composites’ products on the mass market. “It’s like looking at a family reunion photo,” said the presenter. The patterns all have a consistent look, but each one is unique. “The finish process is art done by well-paid employees,” said the rep. In an age when most aspects of gun production are machine-automated, it was a surprise to hear the level of human touch that goes into every composite stock. Commissioned employees start artisan work early in the process, ensuring that each cut stock is a proper fit to its mold. After training, minimum expected production is 48 stocks per week, with most employees producing between 100-200. “We have one guy who turns out 300 per week and they’re all perfect; he is like a machine at his job,” stated our presenter. Stocks are inspected individually by another team before going on to the hand-painting process. High-end, automotive-grade paint priced at $150 per gallon is used for durability and a fine finish. Painters are mostly women who work with sponge application of paint. To the consumer’s eye, the look of a particular stock is consistent. But those in the know can identify individual employees’ work when looking at each stock, as some slight stylistic differences exist. This is also true of texturing. Some stocks have textured grip regions, and this process is also hand-applied to exacting standards. All handwork undergoes inspection before stocks leave the factory.

Employee involvement in AG Composites is key. The company does not accept consumer-submitted art for efficiency and also to keep the factory’s products consistent and tasteful. But that is not to say employees don’t have input. In fact, they have designed some of the signature hunting patterns after being challenged to do so as a team building/recreation exercise. One example is a pattern that has vertical lines, which they speculated would make a good camo pattern because bark grows in vertical lines.

Craftmanship and artistry are built-in, and so is toughness. AG Composites is the only stock maker that heat cures its products. This treatment makes them impervious to hot/cold . This ultimately aids in accuracy since their stocks cannot flex or crack with extreme climate exposure.

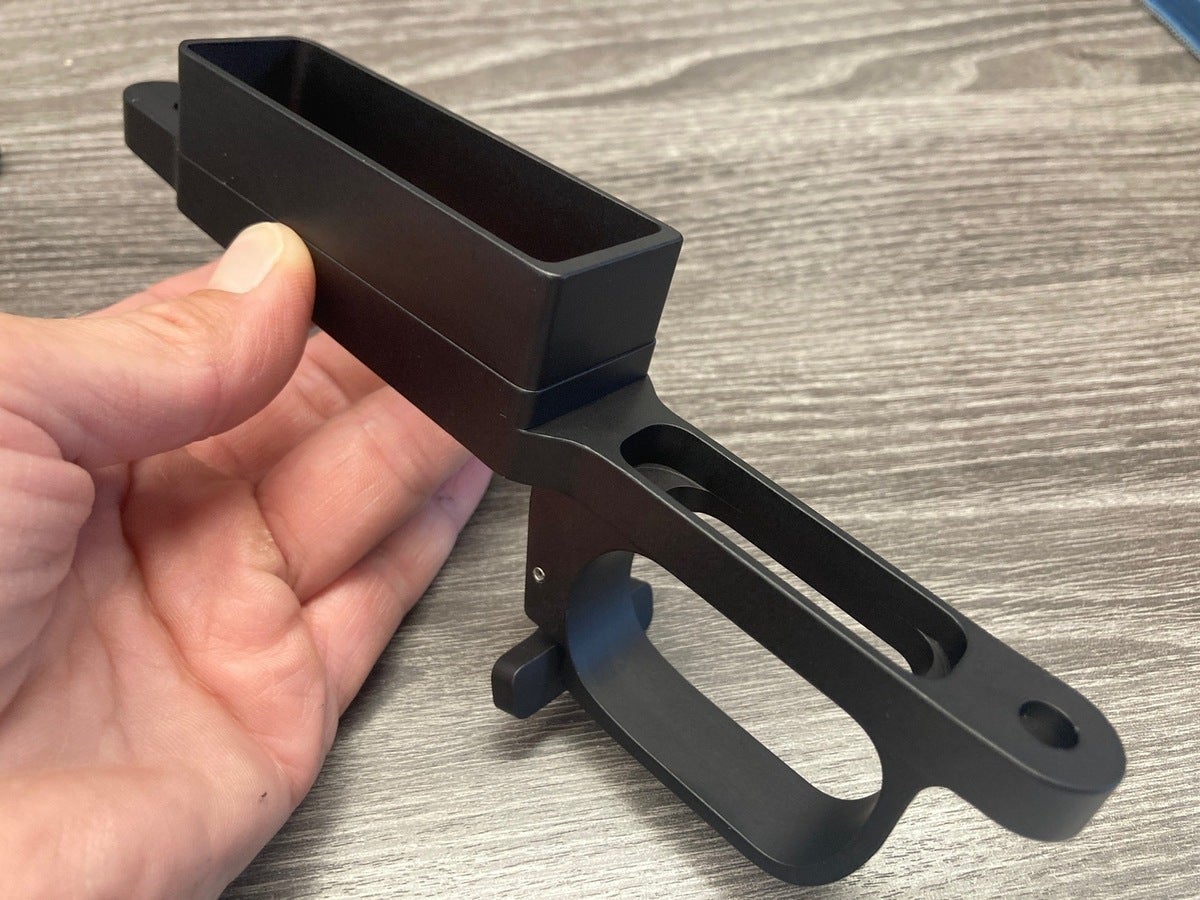

Climate isn’t the only aspect of field readiness with these stocks. They undergo what our factory rep calls “redneck torture tests,” including being run over by trucks, shot, and packed with Tannerite and fired upon – the latter leaving the stock very battered, but still usable. AG Composites also makes the “undermetal” fitments inside stocks. Their aluminum inserts provide strong attachment points for slings, bipods, and such. Lessons learned in this department have led the company to insert longer internal metals because consumers so often change equipment, preventing time and frustration spent by both producers and consumer.

Raw carbon fiber used by AG Composites comes from Spain and is sourced from the same factory as Ferrari and Porsche body parts. Sound pricey? It is, with about $600 in material and production costs going into every stock for an average base price of $725. But a more cost-effective alternative is on the way late this year. That information is currently under wraps. Any number of factory rifles including Springfield and Bergara provide their buyers with a hand-painted, hand-finished AG Composites stock that is similar, but never identical to others in its product line. Current/retired military and first responder discounts are offered.