5 Photos of Firing Pin Repair on a Colt Single Action Clone

Russ Chastain 08.25.17

I’d gotten an Italian-made copy of a 45 Colt single action in a trade, and liked it, but when it failed to go bang every time, I became less fond of it. How to recover my lost love? Repair, of course!

When it failed to fire, it was because of light primer strikes, so I started looking for the problem, after completely unloading the gun, of course. Gotta stay safe.

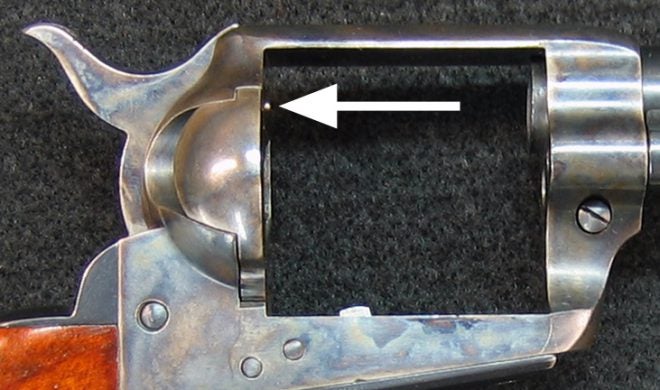

As you can see in the photo, the firing pin wasn’t really protruding forward as far as it ought to. Hmm.

I started looking more closely at the hammer, to see just how things were put together.

The firing pin lies in a hole in the hammer. The hole (right arrow) goes all the way through the hammer, and is of larger diameter up front, where the firing pin (left arrow) is. A cross pin (middle arrow) retains the pin in the hammer, but not rigidly. The pin could wiggle a short distance in & out of the hole in the hammer.

At this point, I measured the distance from rear of hammer spur to tip of firing pin with the firing pin pushed into its hole; I knew I needed to make that distance greater than the 1.660″ I measured.

Using a pin punch barely smaller than the cross pin, I drifted the cross pin out of the hammer while supporting the other side of the hammer. This was the result.

The cross pin is made of soft steel, which is why it is slightly deformed in the middle. That deformation, along with some corresponding deformation of the firing pin, allowed the firing pin to move back into the hammer too far, which contributed to my problem.

As you can see, the pin has been beaten until it began to take on the shape of the firing pin groove. Was this the whole problem? To find out, I reassembled the parts, making sure the cross pin and firing pin were both engaging with virgin surfaces, and again measured from hammer spur to firing pin tip.

The difference was almost nonexistent; simply replacing the cross pin wasn’t going to solve the problem.

I pondered for a few days, and had just about decided to enlarge the hole for the cross pin and use a new, larger, cross pin (which I would have to make and then harden) to crowd the firing pin forward. But the more I thought about doing all that work for a questionable result, the more I reconsidered.

After mulling it over, I finally settled on something simpler. I found a small allen-head set screw at my local hardware store, then drilled & tapped the smaller (rear) portion of the firing pin hole to match the set screw. After deburring the hole at the rear of the hammer, I reassembled the two pins into the hammer, then snugged up the set screw against the rear surface of the firing pin.

I measured the distance from firing pin tip to hammer spur: 1.675 inches; considerably longer than the original 1.660.

The set screw is far inside the hammer, and a casual observer would never notice it. Best of all, I solved the problem without having to build any new parts, no re-drilling of the hammer for the cross pin, etc.

Fortunately, the hammer was soft enough to allow this to work; if it had been better-hardened, I could have had trouble with the drill & tap.

At the range, the old wheel gun went bang every time, and there’s nothing wrong with that.