Making a New Shotgun Firing Pin in 9 Photos

Russ Chastain 08.14.17

A while back, Dad’s old much-worn but treasured Browning Superposed shotgun gave me trouble at the skeet range. When I dug into it, I discovered the top firing pin had broken. After a lot of online searching, I found many firing pins available–all of them wrong for this gun. So I went to work and built one!

My first attempt (not pictured) turned out poorly, but served well as a model of what not to do.

I removed the trigger guard and butt stock, and found part of the broken pin jammed down in front of one of the hammers. Un-good!

I definitely had a problem.

(Photo © Russ Chastain)

I hunted around the shop and decided to use the unthreaded portion of this 1/4″ bolt to make a new firing pin.

(Photo © Russ Chastain)

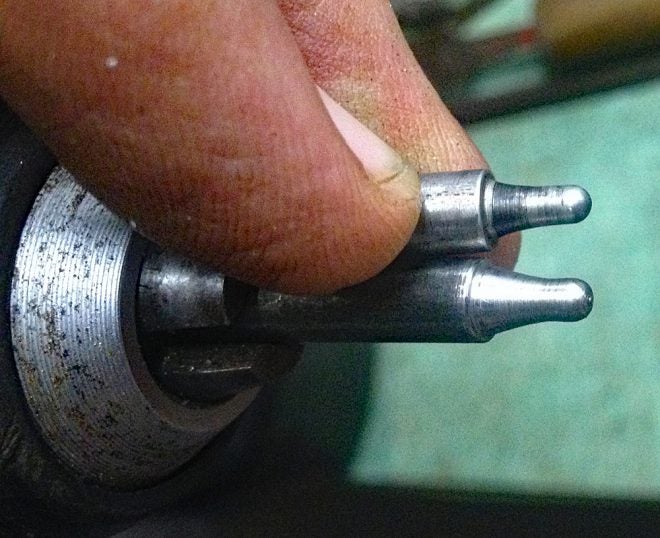

After I turned the bolt down to the correct diameter, I did most of the shaping by chucking it in a drill and using files to form it. Here you can see it taking shape, but still too large on the tip.

(Photo © Russ Chastain)

Once I had the tip shaped and sized correctly, I had to cut a notch into its side. This was easier said than done, because the notch is angled.

I ended up using a small milling machine to cut the notch. I would later fine-tune the notch using files.

Next, I needed to cut the pin to length. Forming the end was tricky, because the pin goes through the receiver at a compound angle (upwards and to the right) and the rear surface of the pin has to be square to the hammer face. And of course the pin had to be just the right length as well.

After a lot of slow, careful fitting and filing, I tempered the pin. This was the final result.

For tempering, I heated the pin red hot and quenched it in 30W oil. It’s been doing well for a couple of years now.

So next time you have a broken part but can’t find a replacement–and if, like me, you have more time than money–consider making what you need.