Meet George Halstead, Country Gunsmith

Russ Chastain 07.11.16

Some months ago, I stopped at a roadside yard sale. It was one of those manly sales, with tools and other good stuff, including some gun items. When the fellow behind the table said he had built a double-barrel muzzleloading pistol and asked me if I wanted to see it, of course the answer was a resounding, “Yes!”

The gun was well-made, functional, and creative. A pair of barrels, side by side, each with its own percussion nipple. A single centrally-located hammer served each nipple via its nifty rotating nose. And he’d made it all himself, in a modest workshop using simple tools.

Photo © Russ Chastain

George Halstead is a mechanic and fabricator who has been working on guns since the 1990s. His father was a tool and die man who worked for General Motors and did gunsmithing on the side, starting in the 1960s. And George’s paternal grandfather was a gunsmith, machinist, and engineer who did gun work from the 1920s into the 1950s. He even once worked on, and was given, a revolver by William “Buffalo Bill” Cody.

Photo © Russ Chastain

As you can tell, transforming metal into useful objects is a Halstead family tradition. And it was George’s son who suggested that he mark his muzzleloaders HCA, for Halstead Custom Arms.

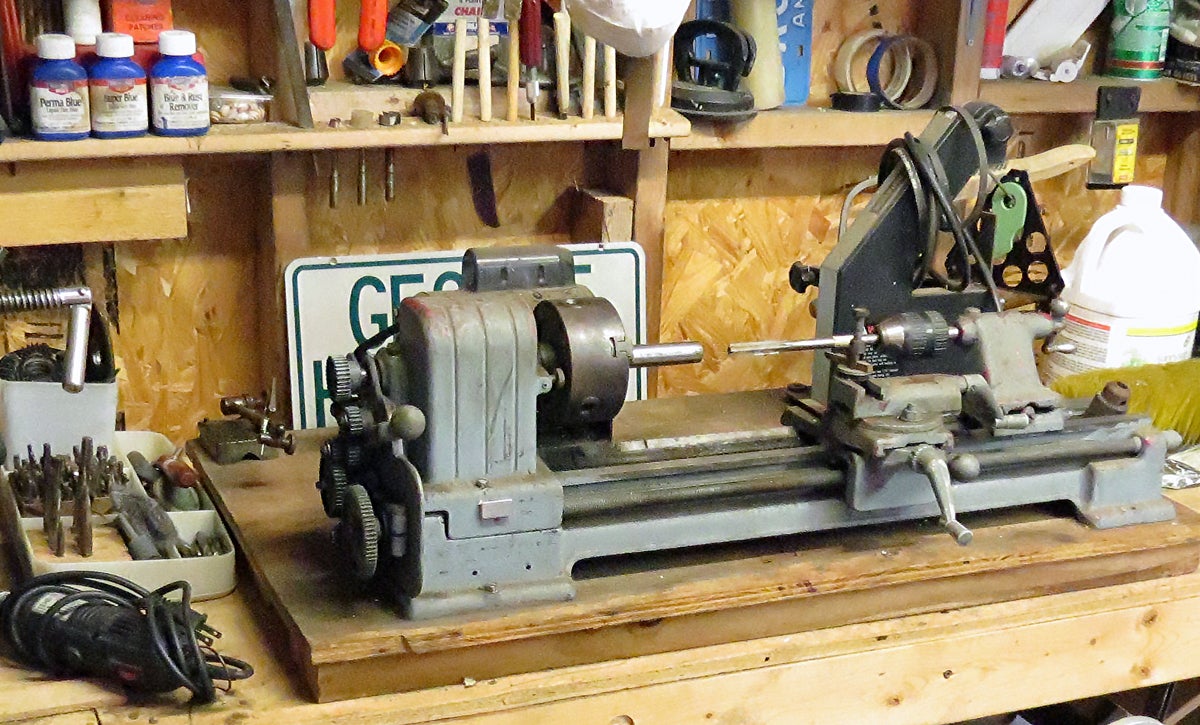

George’s workshop is not fancy. A handmade workbench supports a small lathe, and a drill press is the next-largest piece of equipment. The press serves as a mill, via the sliding mill table.

Photo © Russ Chastain

Photo © Russ Chastain

Most of the work is slow, methodical, and done by hand. Bench-mounted power tools include the lathe and drill press, along with portable tools such as:

- Angle grinder

- Grinder with wire wheel

- Drill

- Belt sander

- Reciprocating saw

- DA sander

- Files

- Welder

- Oxy-acetylene cutting torch

- Dremel tool

Photo © Russ Chastain

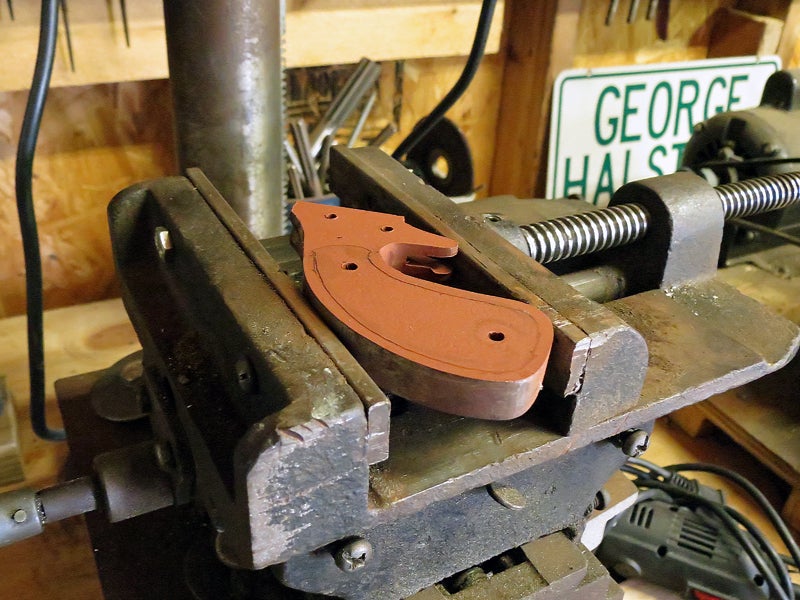

Each frame begins as 1/2″ steel plate, which gets cut out with a torch and manually shaped until it’s suitable for milling.

Photo © Russ Chastain

Gun barrels are 4140 steel and are smoothbore. And his grips, believe it or not, are molded of polymer and fitted right there in his shop.

Photo © Russ Chastain

Frames are powder coated, as are the barrels on his most recent popper. Hammers are hand made and hand fitted, just like everything else.

Photo © Russ Chastain

George is carrying on a longtime tradition of home craftsmanship that is far more valuable in society than most folks realize. Without local people who can build and repair real things, we would all be hosed, especially in even a short-term survival situation.

For more information, check out these articles with details of two of his creations:

HCA Prototype Double Barrel Muzzleloading Pistol

HCA Double Barrel Model MC Muzzleloading Pistol

Mr. Halstead planning to expand his capabilities and is looking to cast bronze and/or aluminum before too long.

Here’s the contact info for HCA:

George Halstead

352-546-3731

23455 NE 160 Avenue Road

Fort McCoy, FL 32134