Why You Should Lap your Scope Rings & How to Do It!

Travis Olander 03.07.23

You just bought some shiny new glass, and you’ve got some rings or a monolithic mount. Before you clamp your scope in your mount and start cranking down those ring bolts, it’s important to confirm whether doing so – even at the proper torque – will damage your optic. Even with low-tolerance, precise CNC machining, scope rings are almost never perfectly aligned. More often than not, a pair of rings (or a monolithic mount’s front and rear rings) will display some amount of vertical and/or horizontal misalignment. Mounting your scope with misaligned rings can result in damage to your scope’s tube or distortion between the objective and ocular lenses.

How to Align Your Scope Rings: Lapping

So, how can you tell your rings are misaligned? How do you fix it and prevent scope damage? Hand lapping is the answer: the process requires using alignment rods that measure vertical and horizontal misalignment, and a lapping rod with sanding compound to hone the rings and align them.

What Causes Misalignment

It’s not always the fault of the scope ring manufacturer for misalignment. Simple tolerances on Picatinny, Dovetail, or Weaver-style mounts can introduce misalignment along the top of the receiver. The coatings and treatments applied to the raw metal on rings can also introduce minor misalignment. This will be evident when you start lapping and honing your rings, as anodizing, phosphate, nitride, or paint gets sanded away to realize raw aluminum or steel underneath.

Getting The Right Tools

For getting the job done, we recommend the Wheeler Hand Lapping Kit. It’s affordable, made in the USA, and it includes everything you need to properly hone your rings. We also recommend picking up an inch-pound torque wrench with a set of Torx and hex-head ring bits. Wheeler makes a wrench-and-bit kit for this purpose.

Scope Alignment Rods

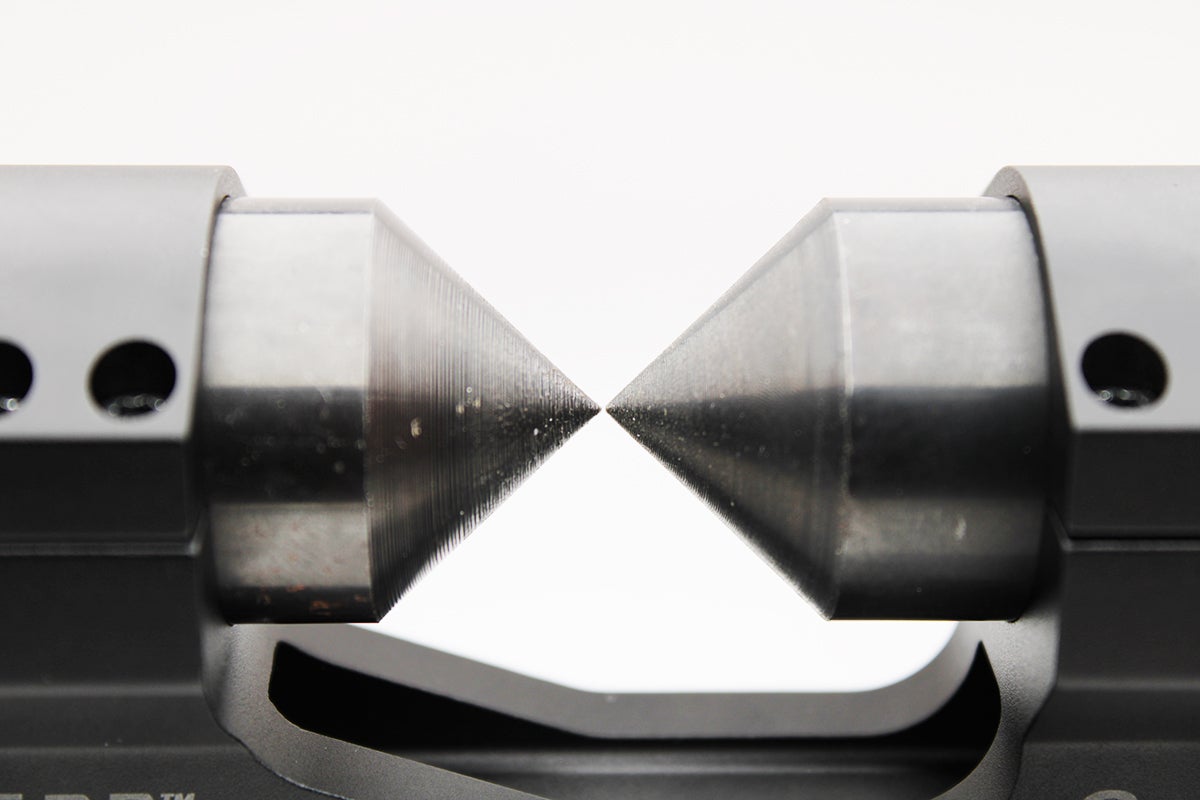

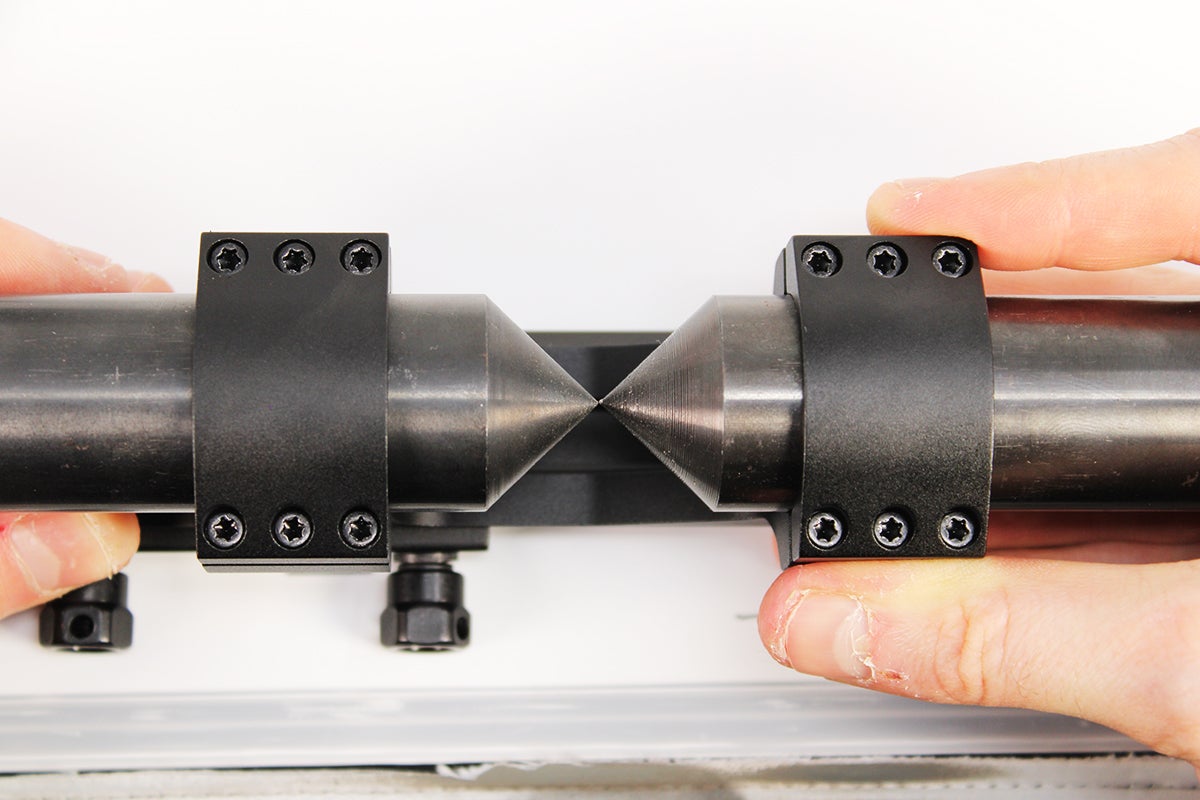

Lapping alignment rods are simple tech: precision-machined from solid steel, the rods are turned to form a perfectly concentric point. Rods come in two flavors to handle all standard rings: 30mm and 1″. To visualize ring misalignment, the rods must be installed in the front and rear rings, and tightened to the rings’ required inch-pounds. Importantly, the rods must be seated in the rings or monolithic mount so their points meet in the middle:

If your rings are misaligned (which, unless you’re spending $250+ on some Nightforce or U.S. Optics mono mounts, they probably will be) it’ll be easily seen. The points of the alignment rods won’t line up horizontally or vertically.

Install Your Mount / Rings Before Lapping

Because ring misalignment can be the result of your receiver’s mounts tolerances, it’s important to keep your monolithic mount or rings installed and properly torqued before and while lapping.

Lapping Your Rings

The lapping rod is a threaded piece of round steel that includes a guide lever for moving the rod back and forth in the rings. This back-and-forth action, paired with the appropriate compound (220-grit paste) is what rounds out and hones the rings to ensure front and rear alignment.

You’ll need to generously apply the lapping compound to the entire lapping rod. This ensures no hot spots develop, so material is removed at a consistent rate along the entire inner circumference of both rings.

Do not over-tighten the rings while lapping. Doing so will result in a stuck rod, or too much material being removed too quickly, which will render your mono mount or rings unusable. The rings’ bolts should be lightly tightened below the required inch-pound rating. They should be loose enough to allow the lapping rod to freely glide and rotate inside the rings.

Stop frequently, and check your work. This is a time-consuming process, and trying to cut corners will likely mean your rings are properly alignment. You should make approximately a dozen back-and-forth passes and full rotations with the lapping rod before removing it, reinstalling the alignment rods, and checking your progress.

As you remove material from the rings, you’ll see the treated or coated finish wear away to reveal bare metal underneath. Even once you’re down to uncoated metal, you may still need to remove more material to get proper vertical and horizontal alignment. Check for where a bulk of material is being removed by properly cleaning lapping compound from inside the rings each time you stop to check your work.

Use alcohol and a terry cloth to remove the compound. On our mono mount, we can see where some ring halves needed more coating to be removed to ensure proper alignment. It’s important you take note of which ring ring halves are paired together during lapping; mis-matching them after lapping could reintroduce misalignment once your optic is installed.

When you’re checking the alignment rods, don’t forget to check from all angles – vertically and horizontally – to ensure the rings are truly honed concentrically before scope installation. Once alignment is verified and lapping is complete, make sure you remove any residual compound from inside the rings and the bolt holes. Getting any compound in side the threads can cause cross-threading, which could prevent proper torqueing or render your rings unusable.