Review of Work Sharp Power Knife & Tool Sharpener WSKTS

Russ Chastain 12.04.19

I’ve been using a Work Sharp electric sharpener for a few months now, and it’s pretty good. Most of my use on it has been with my “everyday abuser” knife, which gets used for anything and everything, from opening food packages and slicing open boxes to cutting dirty, sandy landscape weed barrier material. No matter how much I abuse this knife, I can restore its edge quickly with the Work Sharp Power Knife & Tool Sharpener.

Specs

- Work Sharp Original Knife & Tool Sharpener

- 40° Kitchen Knife Guide

- 50° Outdoor Knife Guide (with 65° Scissor Guide)

- (2) P80 Coarse Abrasive Belts

- (2) P220 Medium Abrasive Belts

- (2) 6000 Extra-Fine Abrasive Belts

- Belt size: 1/2″ x 12″

- Other grits available

- Power Switch: Two-way toggle — can be constant-on or spring-loaded momentary like a drill

- Motor: 120VAC / 0.14 amp, fixed speed

- Duty cycle: 20 Minutes/Hour

- Warranty: 1 Year

- Includes User’s Guide

- SKU: WSKTS

- Price: $69.95

Highlights per Manufacturer

- Interchangeable precision angle guides take the guesswork out of edge maintenance.

- Our premium abrasive belts and flexible technology aren’t just sandpaper, they are specially formulated abrasives with variable belt elasticity to naturally

- Sharpens common cutting tools including scissors, axes, hatchets, mower blades, garden shears, shovels, and most tools with a cutting edge.

First Impressions

After using a Work Sharp hand sharpener that I received in the same shipment, I happily opened the box and pulled out this power sharpener. The only other electric sharpener I’d used before was Chef’s Choice, a fine sharpener but not intended for use on anything other than knives. I do a lot of mechanical shop work as well as yard and landscape maintenance, so I often need to sharpen tools as well. I was eager to give Work Sharp a try.

I keep some scissors in my workshop to cut gasket material, cardboard, or whatever, and they take a bit of a beating. My first pair was pretty cheap and after a bit of work on this sharpener, they hadn’t improved, and one blade turned out to be bent. So I tossed those and went to work on my good shop scissors.

(Photo © Russ Chastain)

The machine comes with three grades of belts: 80, 220, and 6000 grit. To me, this borders on ridiculous for fine sharpening work. The leap from 220 to 6000 is huge! More on that later. For now, here’s an excerpt from my notes:

In the process I decided 220 is too coarse for most sharpening — it shoots sparks so it’s *really* removing material — and 6000 is far too fine. When I was done, my scissors had gotten worse and then ended up more or less as good as they were when I began.

At that point, I had to step away from the sharpener and circle back a little later.

Remodeling a Knife

Picture the scene: Late night, sleep-deprived insomniac, Knife Show on TV. Result: More knives than I can wear out in my lifetime.

When I need an “everything knife,” I dig out my boxes of knives and poke around for something I can keep clipped inside my pants pocket, easy to pull out and open and use for just about anything. The one I had selected was easy to carry and easy to open, but the partially-serrated blade was awful.

(Photo © Russ Chastain)

If you like serrated-blade knives, I’m not sure we can be friends. In my experience, the serrations hang up on stuff and cause a lot of aggravation. Knives were meant to cut, not saw, and my experience with using this knife had brought out many more naughty words than I care to admit. So I decided to get rid of those teeth!

Instead of relying on this sharpener to do all of the work, I used a benchtop belt sander to “hog off” the teeth and prep the blade for actual sharpening on the Work Sharp. I’m sure the Work Sharp could have done the job, but the belts are only 1/2″ wide and I’m not known for great patience.

When I took it to the Work Sharp, I used the 25-degree guide and a 220-grit belt. This stage took a little while because I’d been sloppy on the belt sander and only eyeballed the angles.

When I decided the blade was sharp, I thought it was strange that the “factory” portion of the blade would shave my arm hair but the formerly-serrated part would not. But I decided to hit the blade with the 6000-grit belt, and after about five strokes with that, I could easily shave with the entire wickedly-curved blade. Impressive.

(Photo © Russ Chastain)

The Belts

This brings me back to the belts. While I personally feel that jumping from 220 to 6000 is a long ways to go, that combination apparently serves well for an EDC knockabout blade like this one. And I have another anecdote about the 6k belt. From my notes:

Well I’ve been happy with the knife sans teeth. Dulled the heck out of it cutting landscape material, touched it up with ceramic side of Work Sharp hand sharpener. It was okay but not great.

Later on after I’d used the knife some more and been a little disappointed, I ran it across the used 6000 grit belt one time per side. Holy cow! Just like that it was literally razor sharp.

(Photo © Russ Chastain)

Clearly, this combination of coarse and fine can do the job — so who am I to complain? But if you want something in between 220 and 6000, Work Sharp sells 400, 600, and 1800 grit belts for about ten bucks each. You can also look around elsewhere; 1/2″ x 12″ is a common sanding belt size and other sellers offer them for less.

Changing Belts

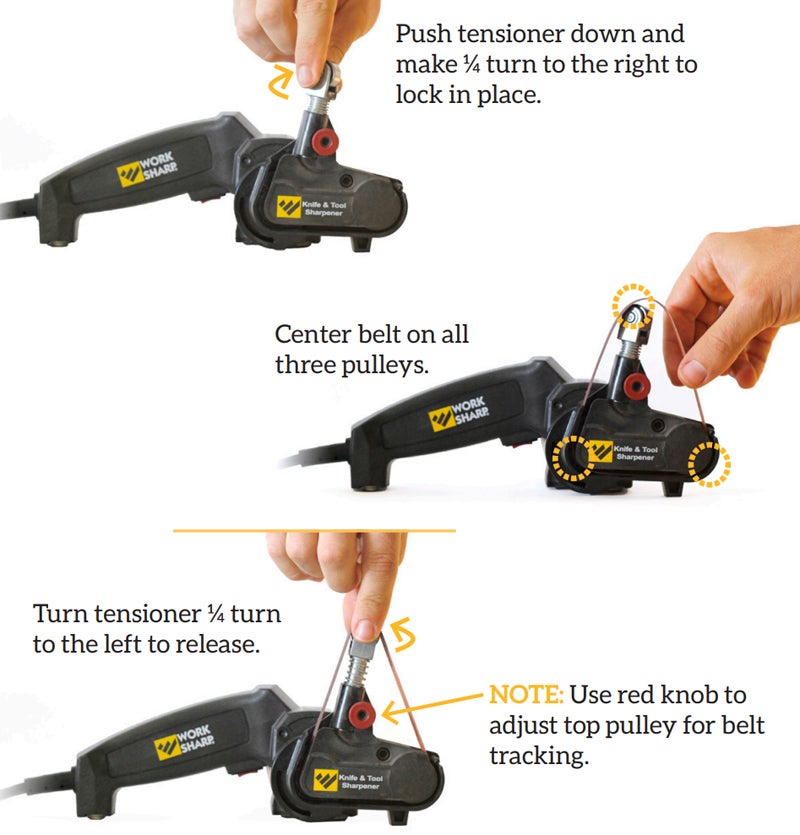

When it’s time to change the belt, be smarter than I am — read the directions. It’s a breeze to swap belts once you learn how to lock the tensioner down. I rarely have to adjust the red tracking knob.

(Photo © Russ Chastain)

Tooling Around

The Work Sharp Knife & Tool Sharpener is small enough that instead of taking your tool to it, you can take it to your tool. For large items such as shovels, you might want to use it as a handheld sharpener. The angle of the head is adjustable to help with that.

I used it on the benchtop to freshen up the edge of a machete, and it did well.

Using the Guides

The two guides included are easy to use. The gray one is set up for 50-degree knife edges and also offers a 65-degree guide for scissors. It also exposes most of the belt, so you can do freehand sharpening or touch up knives with serrated blades. Heck, they even suggest removing the guide entirely in order to sharpen gut hooks!

The black guide covers most of the moving parts and is set up for a 40-degree blade edge angle (20 degrees per side).

Both guides simply slide up (towards the belt tensioner/idler wheel) to remove, and they stay in place well while installed.

IMPORTANT NOTE: To prevent rounding the point of your knife blade, Work Sharp recommends you turn off the power and allow the belt to stop while the blade tip is still against the belt. For this reason, I usually use the “momentary” side of the power switch, and simply release the switch to stop the belt when I get to the knife point.

Other Uses

The User Guide demonstrates how this sharpener can be used on axes, pruning shears, and other blades — although I personally find it far too small for mower blades — as well as using it to deburr, polish, and grind small parts.

In this area, they remind you this is a light-duty tool and is not intended to be used more heavily than 20 minutes per hour.

Final Thoughts

I like the Work Sharp Knife & Tool Sharpener and I will certainly keep it handy around the shop. It makes fast work of touching up my EDC knife, and that’s what I will probably use it for most often — but I also expect this tool to save me a lot of time hand-filing the blades of machetes and brush hooks.

You can currently get one of these sharpeners for $69.95 shipped, and that’s a price that’s tough to beat. Non-OEM belts can be had pretty cheaply, sometimes less than a buck apiece. At that rate there’s not much reason not to give it a try (and to try a number of various grits) if you are serious about keeping your blades safe & sharp — because sharp matters.

Happy hunting.