Reloading Tips Part One: Buying Brass in Bulk

Ron Gunner 10.26.17

So you decided to reload in hopes of saving money for shooting. Fact is, most of time you don’t save money, because the ammo you load is cheaper than the ammo you buy, so you end up shooting more. This in itself is a great thing because we all need more trigger time. Point is, anything we can do to help reduce reloading costs is a big plus.

The first thing you will need after getting your press, dies, and trimmer will be bullets, powder, primers, and brass. Buy in BULK always! You get so much more for your money when you buy this way. I know many people may not have the funds at first to buy a box of 1000 bullets, 8 pounds of powder, and 1000 primers right after the cost of the equipment meaning the press, trimmer, dies, scale, calipers and maybe even a case and/or bullet feeder.

Let’s be honest here, a progressive press with all the trimmings is not cheap, at least one that will last you a lifetime. So if you have to save a little longer to get the consumables, please do so. There is nothing wrong with getting 100 primers, one pound of powder and your saved brass and a small box of 100 bullets just to get your feet wet and get everything set up. But you will see that buying this way will end up costing you more in the long run.

You can buy bullets in a box of 500, and primers are either in a package of 100 or a box of 1000. Powder you can get by the pound, 4-pound, and 8-pound containers. Brass, well here is the first hint — save your own and any friends’ you have that shoot but don’t reload, and pick up range brass, it’s free and usually good for a few reloads.

You need a way to clean brass, and there are a few ways to do this. The cheapest and most common way is tumbling. It works and has worked for decades but it’s a little hassle also. You have dust to contend with that will also have lead and powder residue in it. Then you need a way of getting all the media out of the brass once it’s done.

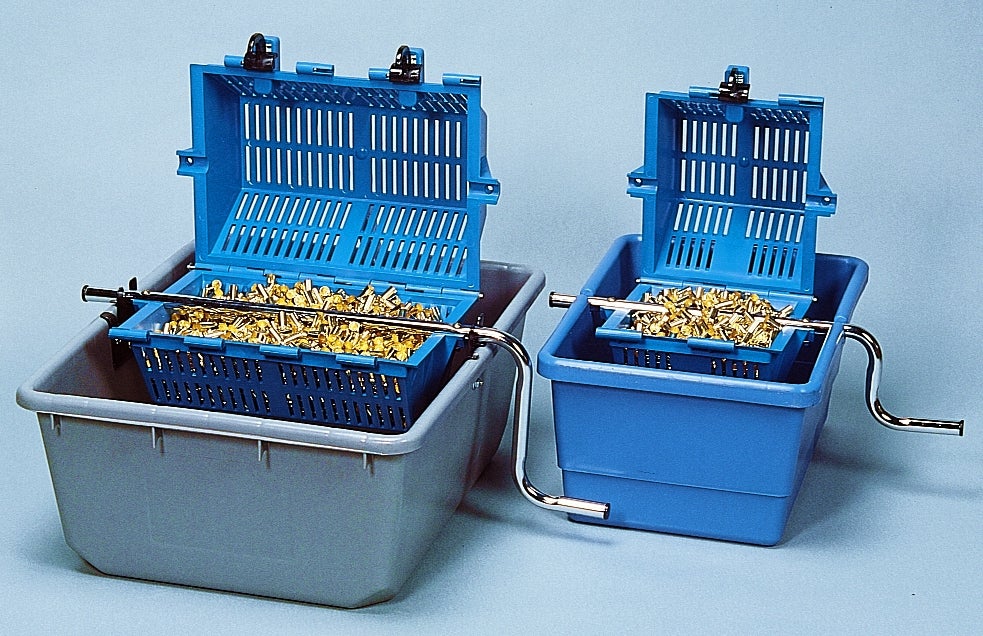

They make a product called a media separator just for this. You load it up with your tumbled brass, and usually you will crank a handle to turn a basket, and the media will fall through the screen.

To get a really clean shiny look to the brass you can add to things in with the media. One is some sort of liquid metal polish; I use Flitz myself. Then you can also add cut-up Scotch-Brite pads. I cut mine into 1-inch squares and add maybe 20 to 30 of these in with the media. Between the media, Flitz, and pads, your brass will be very clean!

Another way is “wet tumbling” using stainless-steel pins in a sealed tumbler with some sort of additive in the water. You let it tumble for a couple hours and they come out looking like new. Sometimes if you have removed the primers before cleaning, the little cleaning pins will get caught in the flash hole. So be careful and watch for that. Wet tumblers cost more than the vibrating tumblers talked about above.

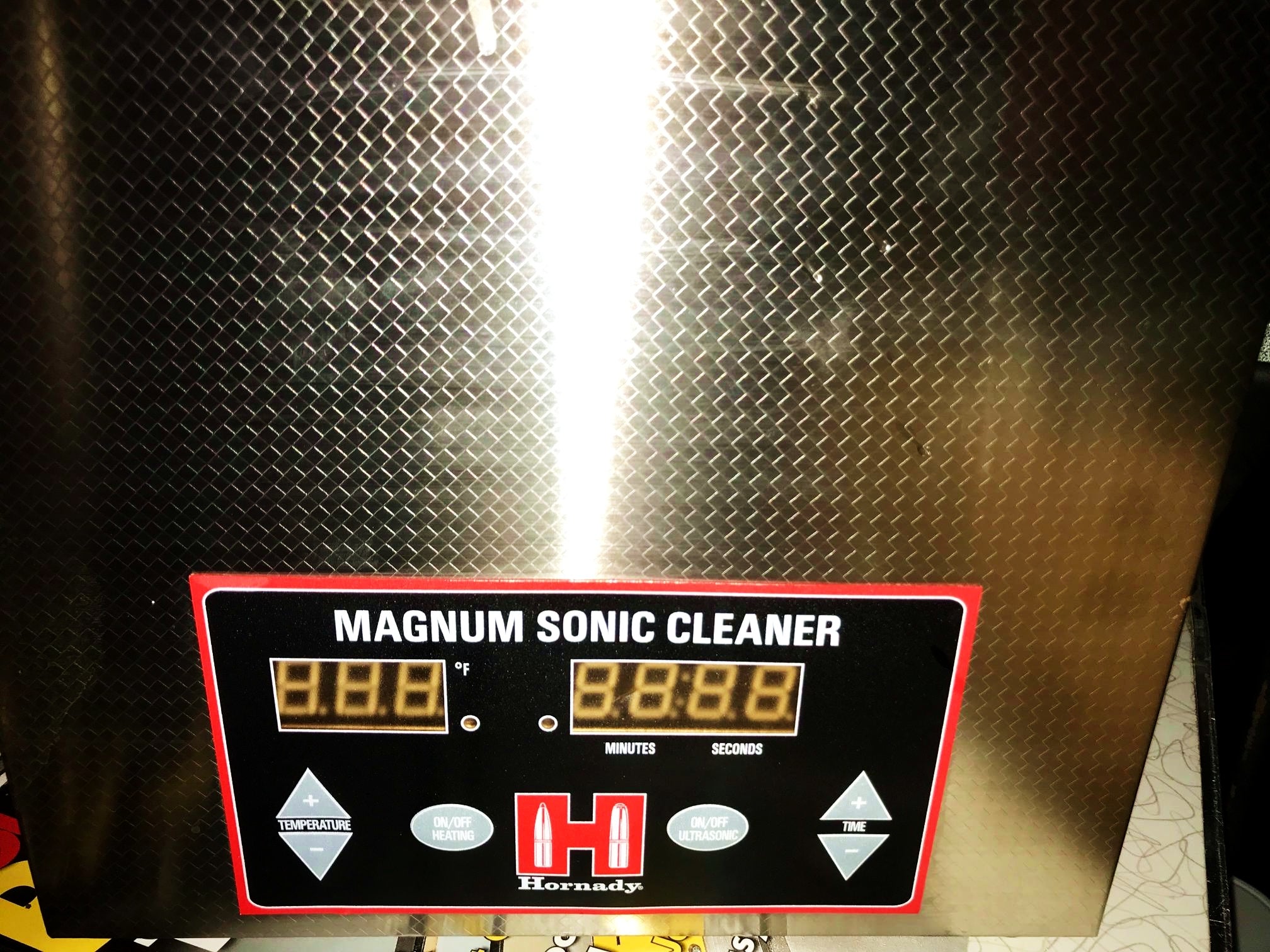

Then there is my personal favorite, “Sonic Cleaning.” You have water and brass cleaner in a system that will “sonic clean,” meaning very small, fast ripples (for lack of a better word) that will clean everything inside and out. There are no steel pins nor dust to worry about. My sonic cleaner is a Hornady 2Ltr with a timer and heater. I set it for 170-degree water and clean shells for 60 minutes. The brass comes out like new.

For both wet tumbling and the sonic cleaning you will need to dry the brass before you store it or load it. Some people spread the brass on cookie sheets and stick them in the oven for “X” amount of time. In the summer, some leave them outside in the sun. I take mine, open a big towel, put the brass in the middle of the towel and fold it over, then twist the ends of the towel. At this point I take the towel one end in each hand and hold the towel so it is straight and tight “horizontal,” then move my arms left and right over and over at a fast pace for about a minute.

That gets the most water out. Then all I do is tilt the towel up on one end and let the brass fall down a little to a dry spot of the cloth. Then grab the towel so the brass stays in the dry spot and repeat the shaking back and forth for about 3 minutes and the brass is dry.

This is part one of a multi-part article on reloading and tips that will help you save money, so look for more parts coming your way!