Bond Arms Factory Tour

Major Pandemic 04.30.14

I am fortunate that my day job takes me all across this great country, and I found myself on the far Southwest side of Dallas Fort Worth and close enough that a trip to Granbury, Texas was not an epic adventure. The trip to Bond Arms was both fun and educational. I met the owner, Gordon Bond, many of his staff, and of course his robots — yes, robots.

The first task is to actually find the Bond Arms facility, which is actually a task in itself. Gordon loves his customers, but his secure facility is not equipped to handle visitors. In fact, the facility is surrounded by a security fence with an electronic gate, and the entry is also secured by a giant steel gate with Bond Arms handgun handles.

After pulling open the massive door, Gordon greeted me and pulled me into his office to talk about the background of Bond Arms and to walk through how his handguns are produced.

You will notice I keep saying Bond Arms “handguns” and not Bond Arms “derringers.” Gordon noted that the “derringer” name has been really tainted as a cheap/junk gun, and in some cases these guns lack the durability to safely shoot the round they were intended for. Bond Arms handguns are a different class altogether. From my perspective, Gordon is not blowing smoke on that claim. Bond Arms’ handguns are among the finest “derringer style” handguns ever made, and some of the highest craftsman handguns of any type.

Part of that quality is due to Gordon’s brother, the original founder, taking a derringer design and then completely redesigning nearly every aspect of the firearm. The Bond frame itself is not a cheap alloy or inexpensive carbon steel — each Bond handgun is made from wax loss stainless casings. This delivers a superior frame to any other double barrel handgun on the market. The safety was also redesigned to move from left to right versus the other way around to allow the safety to be kicked off with the right hand thumb.

The hammer was widened to ease cocking, and a completely new rebounding hammer design was created to deliver the safest and fastest double barrel handgun out there. The Bond Arms hammer transfer bar auto-indexes to the next barrel, so all you need to do is shoot-cock-shoot versus worrying about kicking a switch over to another barrel. Additionally, the hammer will not hit either top or bottom firing pin without the trigger being fully depressed. A removable trigger guard was added for those that wanted an extra margin of safety.

The extraction system was also redesigned to actually work, and the action itself was designed to lock more securely, deliver a more ergonomic opening, and offer barrel interchangeability. One of the features of the Bond Arms handguns is that any barrel length and caliber offered by Bond Arms can be swapped out with any Bond Arms frame. Gordon went a step further and created sets of various grips and grip sizes, which can also be swapped between the frames. Technically, all the Bond Arms frames are the same, though some models feature different finishes or have a removable trigger guard. So if you have a Bond barrel, it will fit on any Bond lower receiver. This firearm interchangability is one reason Bond owners keep coming back for more barrels, more handguns, and more accessories.

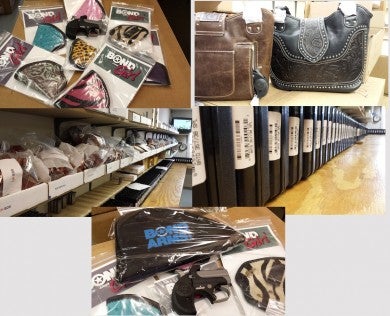

Bond’s accessories are impressive as well. I can not think of any other firearms manufacturer who has put so much thought and care into their accessory line. In fact, I doubt any other manufacturer has an accessory line as comprehensive. Bond Arms features a huge array of gun barrel options ranging from .22lr to .410/.45 Colt in many different lengths; grips that range in size shape, material, and color; knives; leather, hand crafted CCW purses; very high quality holsters that include CCW; Nylon apparel; the “Bond Girl” accessory line; and display boxes. Bond has everything you need to accessorize, carry, load, and show off your handgun.

Wait a Minute… A Two-Shot Hangun as a Defense Gun?

I will get into this topic in a deep follow-up article, but the answer is the Bond Arms two double barreled handgun is a viable defensive handgun with substantial stopping power in the larger range calibers. One of Bond Arms customers used a .410/.45 Colt chambered version to instantly incapacitate an attacker with one shot. Moments later, the attacker died. The .410 Buckshot load has proven to be a devastating man stopper statically beyond that one attack.

Statistically, 99+% of attacks only involve 1.25 shots from the defender; which indicates that almost no attacker likes to get shot twice. Personally, I would rather have an G20 10mm on my hip with my DPMS GII .308 over my shoulder with hard plate body armor on. But sometimes concealment, rational judgement, or convenience dictates just a Glock 26, a slim Walther PPK, or in this case an extremely concealable double barreled handgun slipped in a front pocket. I generally prefer to have my Glock 19 on my side, but there are times where that does not work with my wardrobe. I feel perfectly well armed with a Bond Arms handgun. I like them so much I have two handguns with barrels in .45ACP, .410/.45 Colt, and .357 Magnum. Shoot them once and you will be smitten.

Back to the Factory Tour

After the production overview, we headed out to meet his staff, see the production process in action, and say hello to his robots.

The raw wax lost casings come in and are precision CNC milled to exacting dimensions. After that they are handed off to the yellow robot twins. Gordon wanted to employ robotics to deliver about 60% of the frame and barrel’s precision grinding, finishing, and polishing.

The main drive to robotics for Bond Arms was that it would take nearly a year for a person to reach the level of speed, precision, and accuracy that the robots can achieve on this extremely critical high-skill finish step. A major issue Bond Arms was able to overcome with robotics was removing the potential for sickness, personal schedules, vacations, turnover, and personnel issues to impact this critical production step, which had previously halted and backed up the entire production process.

Gordon has been working for over four years with a robotics team to create this use of robotics in the firearm industry — to my knowledge it is an industry first. That effort and the production capacity and efficiency has allowed the set of robots to pay for themselves in just over a year. I was certainly fascinated, but the robots deliver entertainment value as well. Gordon’s granddaughter also loves to set and watch “yellow,” as she has named them, for hours according to Gordon.

After that step, the frames are handed over to skilled finishers who perform the final 40% of finishing and polishing before firing control and grips are installed. The barrels follow a similar CNC milling and finishing process, but they begin as billet stainless steel, versus cast wax loss forming. The barrels are CNC machined bored, rifled, chambered, finished via the robots, and then passed to final assembly. The barrel and receiver meetup and are paired based on customer and dealer orders. Although Bond Arms has established quality control steps at different points in the production process, they perform one last complete inspection, along with functionally test firing each handgun in their in house test range.

Of note, Bond Arms attempts to reuse and recycle almost everything. Packing is reused and even the massive crates from the robotics were recycled to create portions of the shooting range and the range table. They specifically added the indoor test range to cut down on the drive time required to test fire the guns at a local range. Bond Arms is cutting edge in many aspects and even a bit green as well.

Final Thoughts

It’s a funny thing to be out in Granbury, Texas and meet two robots. In fact, what Gorbon Bond is doing is nothing short of amazing as I could find no other reference to automotive robotics being used in the firearms industry. He actually was told by over a half dozen robotics firms that it could not be done, but one company shared his vision and now Bond Arms could be the most technically advanced manufacturing firearms company anywhere because of it.

Bringing a firearm to market is tough, even in the current gun sales bonanza environment, but Bonds Arms has continued to grow since it was founded in 1995. Part of that recipe has been the quality and service they continue to offer at a premium level, plus a drive to continue innovation far beyond the norm of even very large firearms industry giants. Really, the titans of the firearms industry should be touring Bond’s facility. Pick up a Bond Arms handgun and you will immediately be impressed with the quality of the firearm. Bond Arms have delivered thirteen SASS (Single Action Shooting Society) world championships, so there must be something to these firearms, beyond just showpieces.

Look for an upcoming review of these great high quality handguns. The factory tour left me impressed to say the least.