3D Printing Knife Scales

Ashley 07.25.14

I’m a fan of making tools by hand, and this extends into modifying tools, too–an old practice among longtime EDCers. The longer one owns a tool like a knife or a multitool, the stranger it seems to not modify it to suit his or her needs. Although I’m just a hobbyist, I currently have a few 3D printers in my possession, and I decided to try my hand at making some 3D printed scales for my Kershaw Cryo. The Cryo is a popular knife to modify, and there’s no shortage of custom handles available for it. It’s personally one of my favorite EDC folders, although it’s been criticized for having a slippery handle, which can be problematic when using it for intensive tasks. I thought a plastic scale on one side of the knife might aid in fixing this, and it was a simple way to improve the aesthetic of my folder.

The 3D printer I use most often is a MakerBot Replicator 2, which only prints in PLA plastic. PLA isn’t the best material to use for reliable knife scales–I’d probably pick G10 for that–but 3D printers are intended to be used for rapid prototyping. My other printer, also a MakerBot, uses ABS plastic–PLA tends to be more rigid than ABS. I needed a material that wouldn’t shatter if I gripped my knife too tight.

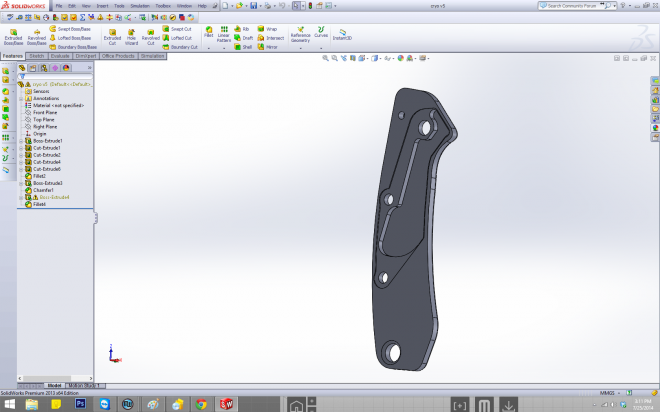

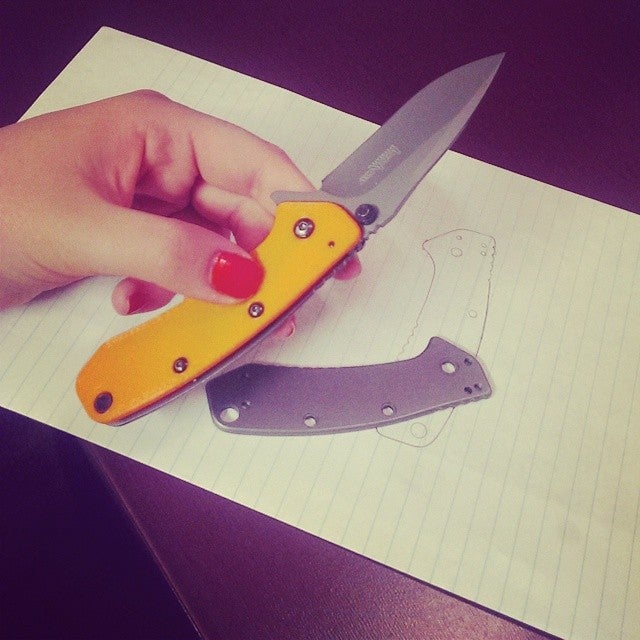

To start the process, I first needed to design the scales virtually. I collaborated with my boyfriend, Andrew, who’s an engineer and CAD designer, to make the scales in Solidworks. If you do some sleuthing on the web, you can find the dimensions of Cryo scales; but we wanted to be able to better customize future designs, so we made ours from scratch. We disassembled the Cryo and used the thin scale as a reference, employing a caliper to measure out each component of the existing Cryo handle. It took a while but we were eventually able to design the scale with the correct dimensions.

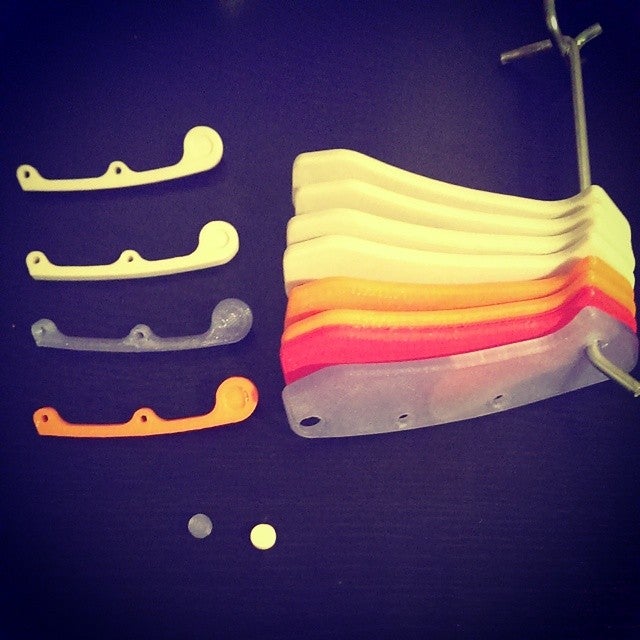

After the scale was designed, we decided to print one to test the fit. We first used an off-white PLA, which actually looked pretty good contrasted with the gray color of the Cryo.

Although it looked nice enough, it wasn’t fitting the knife as comfortably as we had hoped, so we took some new measurements and very slightly altered the Solidworks model. One of the changes, for instance, was making the lower right corner a bit less rounded to better match the shape of the existing Cryo scale. This made the second version–orange–fit much more accurately to the knife.

Once the basic scale was to our liking, we wanted to make some other accessories to make the knife look more complete. We designed some spacers–which proved to be more difficult than the scale since it required some measuring of the knife’s internals as well some bolts to fill in the paracord hole.

I found that the new scale made the knife significantly lighter, which in turn, makes it a more comfortable pocket carry. The slippery handle has also improved, as the PLA has a bit of a grit to it that makes it easier to grip.

I’m pretty pleased with the first versions of these accessories, and I’m looking forward to designing scales for my other EDC knives (which include the popular Ontario RAT and the Spyderco Tenacious). Other makers have experimented with 3D printed Cryo scales, too, including designer David Thompson, who has made some beautiful scales with unique patterns.

Considerations for 3D printing tool handles:

Material: 3D printers come in various models and can print different types of material. Depending on how you plan to use your tool, that may impact which printer and material type you prefer.

Infill: PLA is a decently strong plastic, especially for an EDC knife handle that is mostly used for smaller to medium tasks. Regardless, we chose to do a fuller infill to make the scale really durable. If you want to lighten a knife, a lesser infill will also do the trick.

Color/Texture: Designing the scale using 3D modeling software means that you can add some great designs and textures to a scale prior to printing it. Although some 3D printers can print in more than one color, most are still one-color only, so think simple when coming up with a design.

Disassembly/Reassembly: Disassembling a beloved folder can be tricky, as there’s a chance that it might not fit back together the way it was before. Be sure to seek guidance on webforums about proper disassembly, and be careful to not lose any tiny components while taking apart your knife.

Interested in prototyping a knife scale? Locate a 3D printer or a CAD designer near you through MakeXYZ.